Preface:

With the increasing global energy shortage and environmental protection requirements in recent years, LED has been widely applied in lighting due to the features of environmental protection, energy conservation and high efficiency, and its service life is concerned. The service life of the LED light mainly depends on the quality of the LED driver power supply. The driver power supply is also critical to the improvement of the LED industry chain and directly affects the reliability of LED products. Therefore, it is essential to improve the LED driver power supply along with gradual progress of the LED industry. The prompt and advanced solution can be provided by the IT7300 series AC power supply of ITECH Electronics (ITECH) for the test of the input end of the LED power supply to ensure the accurate and efficient test of the LED driver power supply.

Text

The LED power driver is a kind of power supply to drive LED. It is used for converting the power supply into the specific voltage and current to drive LED to emit light. With rapid development of the LED technology, the requirements of the LED driver power supply are also increasing. High efficiency, surge protection capability, long service life, waterproof performance, moisture-proof performance and electromagnetic compatibility have become key indicators for evaluation of the LED driver power supply. Therefore, power supply manufacturers and lamp manufacturers pay more and more attention to the advanced testing and measurement technology and solution.

The IT7300 series programmable AC power supply of ITECH can be used in such solution, and is capable of simulating normal and abnormal AC inputs and measuring the important electrical parameters of the tested objects. It is equipped with the standard LAN, USB and RS232 communication interfaces and has the desktop and system properties. Therefore, the multi-purpose solution can be provided according to the design and test needs.

I. High Efficiency Test

LED is an energy-saving product; therefore, the efficiency of the driver power supply should be high. This is particularly important to the structure with the power supply installed in the lamp. As the light-emitting efficiency of LED decreases along with the temperature rise of LED, LED cooling is critical. If the efficiency of the power supply is high, the power loss is small, and the amount of heat in the lamp is small. Therefore, the temperature rise of the lamp can be reduced, conducive to the delay of the LED light attenuation.

Test Method:

With the function of voltage and frequency adjustment, the voltage and frequency changes of the input end of the LED driver power supply can be simulated by the IT7300 series AC power supply. With the SWEEP function, the voltage and frequency fluctuation output can be set according to different requirements. With the high-accuracy measurement function, no AC power meter is needed to test electrical parameters, such as the RMS voltage/current, actual power, power factor, apparent power, peak current, etc., and the measurement resolution can reach 0.01W/0.1mA, meeting the requirements of the Energy Star standards.

II. Surge Protection Test

LED has poor anti-surge capability, especially the reverse voltage resistance. It is important to strengthen such protection. Some LED lights are installed outdoors, such as LED streetlamps. Due to the swinging and lightning induction of the power grid load, various surges will enter the power grid system and LED will be directly damaged by some surges. Therefore, the LED driver power supply should be capable of suppressing surge intrusion to protect LED from being damaged.

Test Method:

With the flexible function of waveform simulation, the IT7300 series AC power supply can simulate the test of the transient breaking wave and specific phase angle opening/closing of the power supply, the test of the AC power supply disturbance (PID) and the immunity test complying with the certification regulations of IEC61000-4-11 to IEC61000-4-14 and IEC61000-4-28.

III. Long Service Life Test

Compared with the traditional lamps such as the incandescent and fluorescent lamp, LED has the obvious advantage of long service life. However, the advantage of no influence on the service life in case of frequent switching is only limited to LED itself. The long-time normal use of LED mostly depends on the LED power supply. The advantages of the LED can be utilized only when the LED power supply has a long service life.

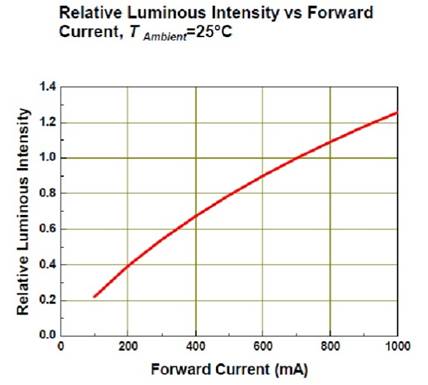

The following figure shows the relationship between the relative luminous intensity and forward current of LED. As shown in the figure, the relative luminous intensity will increase with the forward current increasing. If the ripple current is too high, the luminous intensity will be uneven, and the LED temperature will rise, affecting the performance and service life of LED. In case of no or low ripple current, the luminous intensity will be even, the LED temperature will be stable, and the service life of LED will be maintained.

Test Method:

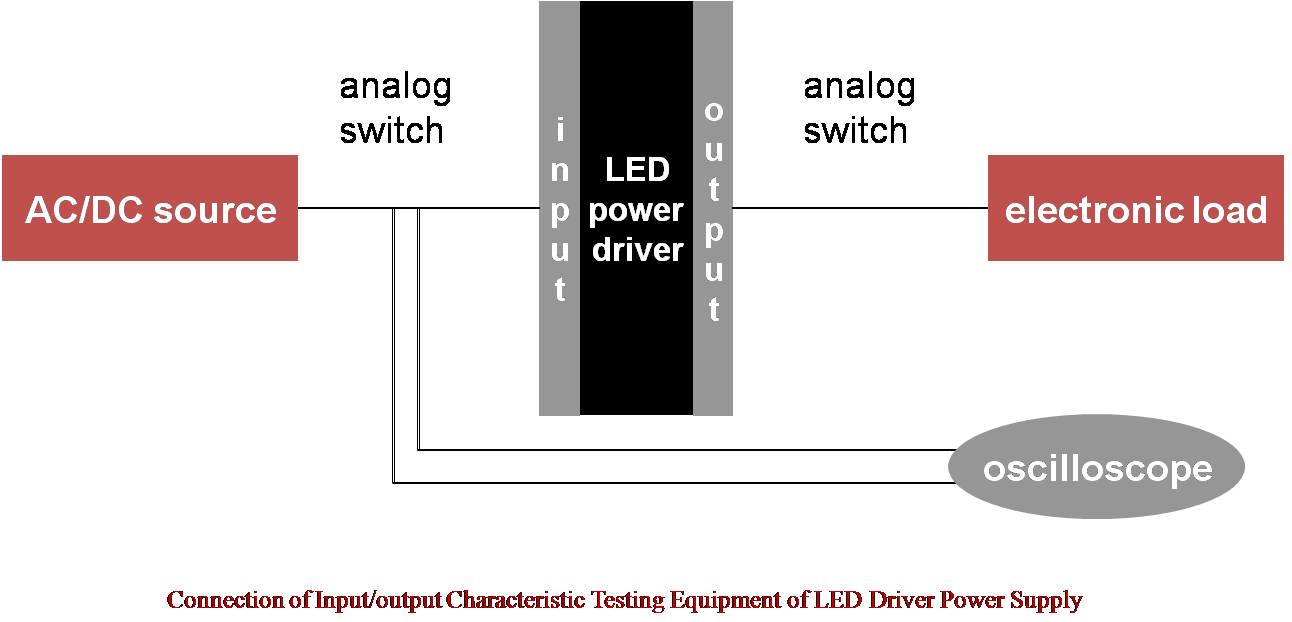

The driving capacity of the LED power supply and the influence on LED are judged according to the ripple current of the LED power supply tested by the IT7300 AC power supply after AC-DC conversion. Note that the output end of the tested LED power supply should be connected to the filter capacitor in parallel before the test and the bandwidth is generally limited to be 20MHz.

Conclusion

ITECH provides comprehensive test solutions for the LED field, based on the deep study of related tests of the LED industry, full consideration of actual needs of most engineers and professional experience in the power supply testing field, including IT7300 series programmable AC power supplies and IT6200 series programmable DC power supplies for the input end as well as IT8912E dedicated electronic loads for LED tests. Using the broad production line, ITECH has also developed the ITS9500 automatic test system of the LED driver power supply, which is applicable to detailed inspection of products by the R&D department and quality control department and can be used for testing batch products at a time on the production line.